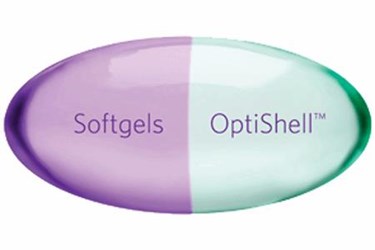

Solutions For Challenging Compounds Using Softgel Innovation

Source: Catalent

access the Application Note!

Log In

Get unlimited access to:

Trend and Thought Leadership Articles

Case Studies & White Papers

Extensive Product Database

Members-Only Premium Content

Welcome Back! Please Log In to Continue.

X

Enter your credentials below to log in. Not yet a member of Clinical Leader? Subscribe today.

Subscribe to Clinical Leader

X

Subscribe to Clinical Leader